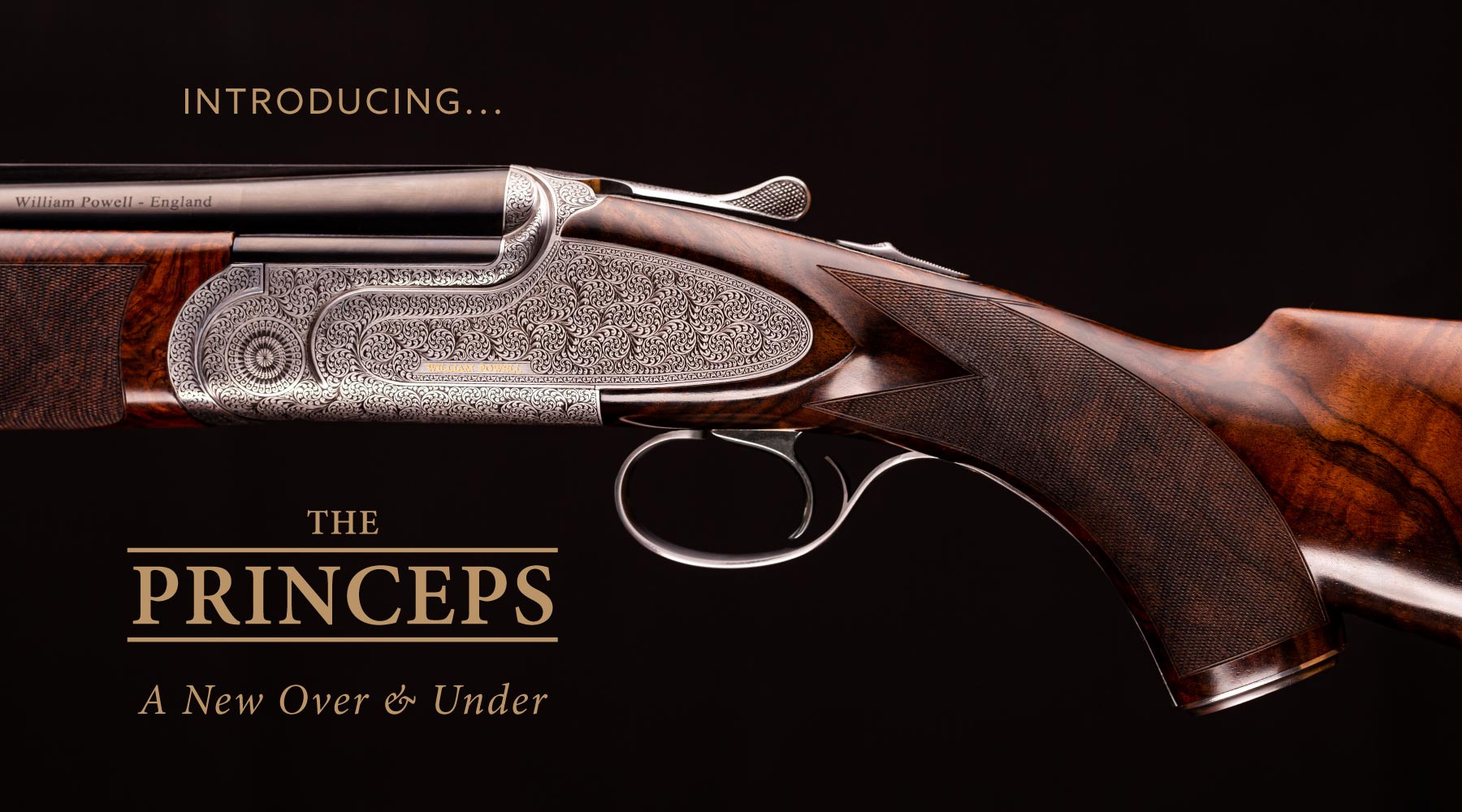

Purveyors of quality, reliable, made to measure shotguns

Since 1802 William Powell has been a trusted name within the Gunmaking industry. Over the last two centuries, the world of game shooting has evolved, and we are proud to be at the forefront of this industry, working with other established makers and the finest craftsmen to bring you futureproof shotguns which offer unrivalled performance, classical beauty and exceptional value for money.